Robotic Cutting and Welding Solutions

What RHINO Can Offer

- Complete turn-key solutions with comprehensive in-house expertise:

- Part review and design for laser consultation.

- Production run capabilities

- Advanced tooling & fixturing for laser processing.

- Robotic path work and controls automation programming.

- Laser parameter development based on extensive knowledge of laser processes.

Contact Us

Robotic Laser Cutting

Rhino uses high-precision robots paired with the most advanced cutting optics in the industry to provide the most accurate and repeatable cutting results. Our engineered solutions are built with increased rigidity and stability compared to many laser cells on the market today.

- Ultra-high strength steel structures (Hot stampings)

- Pipe & Hydroformed tubular components

- Automotive body panels

- High precision cutting for aerospace

- High-performance robotic laser cutting cells from Rhino Cutting Systems.

- In-house engineering team with proven track record in designing complex machines

and offering customized SOLUTIONS. - Advanced Laser know-how, applications support and laser safety officers on staff

with years of metal cutting experience.

Robotic Laser Welding

Rhino has the expertise and experience needed to achieve consistent, successful results in Laser Welding. After careful review of the customer’s specific process, we can pair the correct optical configuration to the application — whether it be: fixed optical head, 2D/3D scanning, or laser with wire feed. Additionally, we offer advance multi-dimensional weld process monitoring to attain the highest production reliability.

- Door rings and structural pillars

- Roof panels

- Powertrain components

- Electric car components and battery trays

- Seating assemblies

- Weld monitoring and analysis for process verification

- Seam Tracking and Auto Focus

- Gap measuring and Depth validation

- Joint position tracking

- Real-time process monitoring

- Data tracking and storage

- Application Improvements

- Avoiding micro-cracks and porosity…

- Power modulation

- Beam Shaping dual core technologies

- Beam oscillation or Stir welding

- Shielding

- Filler wire

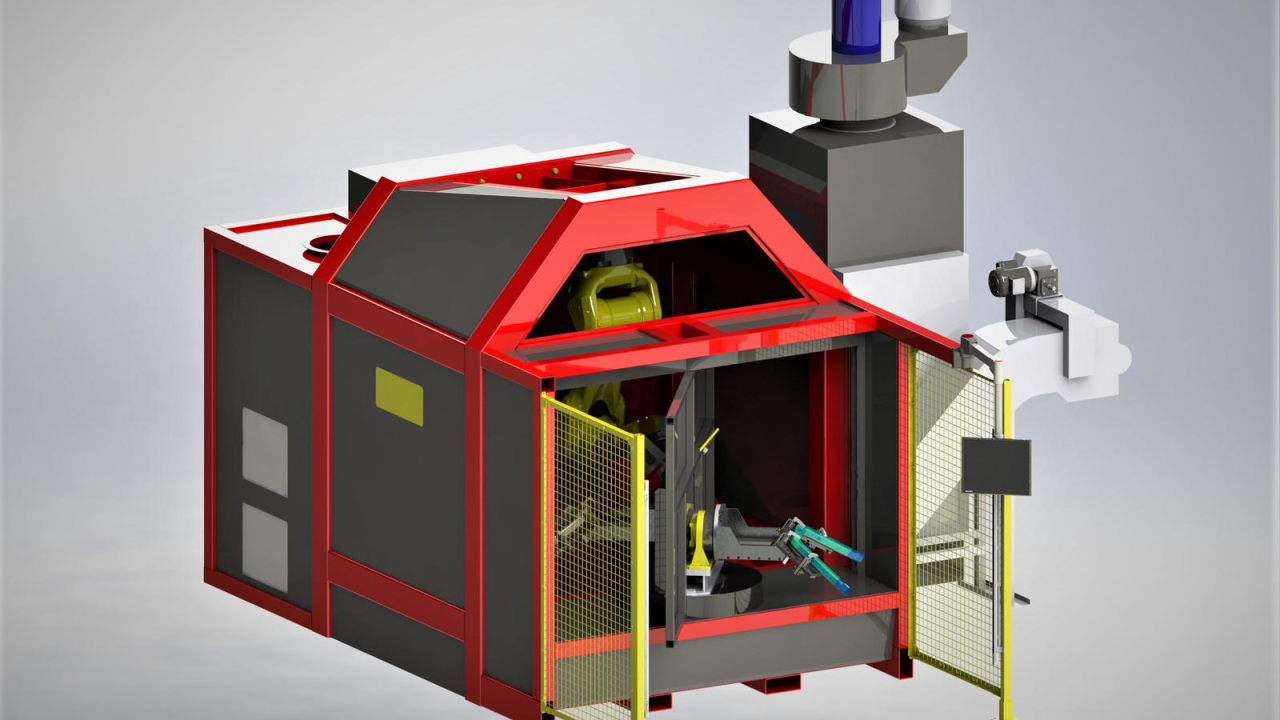

Laser Cell Design Features

- CDRH Class 1 Light-tight laser enclosure with viewing windows

- Space saving design

- Safety-interlock systems

- Dust collection with Spark Arrester.

- Integrated cable management and protection.

- Internal lighting to illuminate work area

- Optional Internal process view camera with externally mounted video monitor

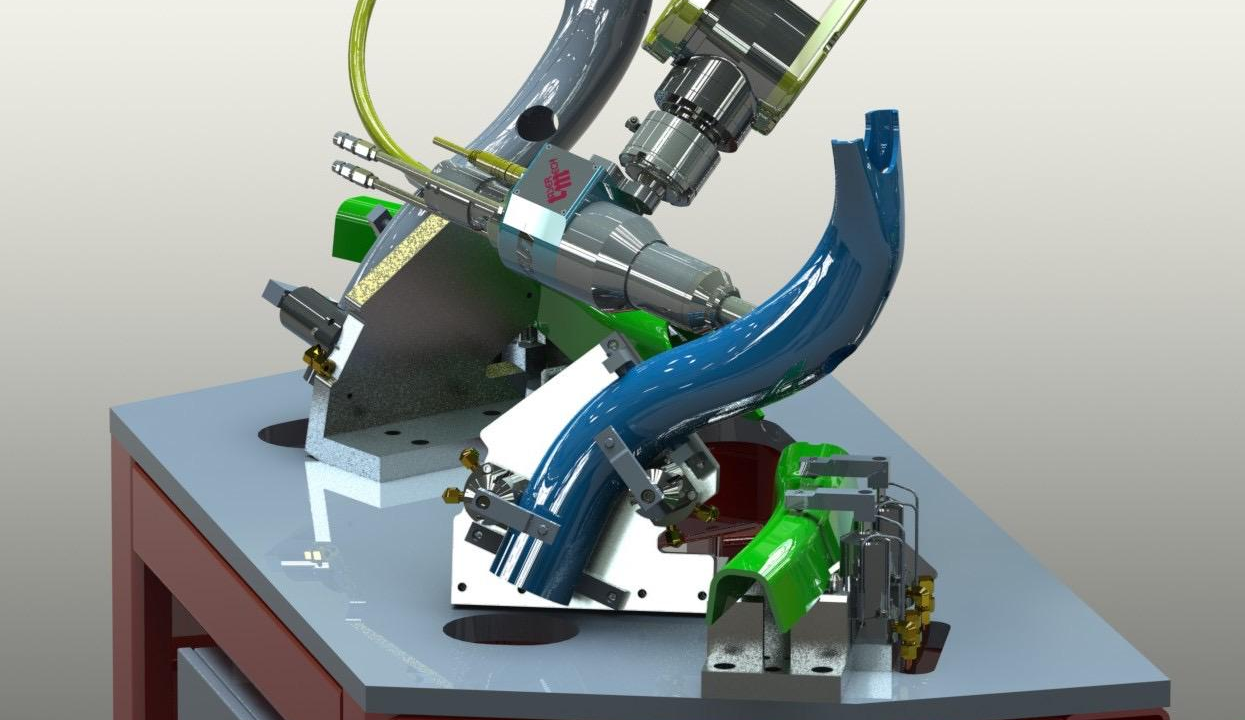

Part Fixturing

Everything done in-house with continual client assistance. We provide the fixturing that your part may require. These dynamic clamps are specific for laser processing and can be provided hassle-free, directly by the Rhino team when requested.

Robot Integration & Programming

- Full path work development

- Highly accurate and repeatable process

- Quick & easy adjustment of cut elements during production

- Customized HMI screens

- Minimized production interruptions for path corrections.

- Integration of fixed laser optic or more sophisticated trepanning head available

Software Features

Simulation software to pre-run new parts and processes offline

Easy to load 3D part files and overlay new 2D cut path work.

Advanced shape tuning available to increase accuracy of small holes

Pre-loaded shapes and quick add features to add new cut outs and locations.

Strategic Partners

Previous

Next