Streamlining Production: A Study of the Top Industries Embracing Robotic Welding Technology

Robotic welding techniques can be applied in various fields, including metalworking and railway applications. Automated welding can be an excellent solution for any complicated metal jobs your business may require.

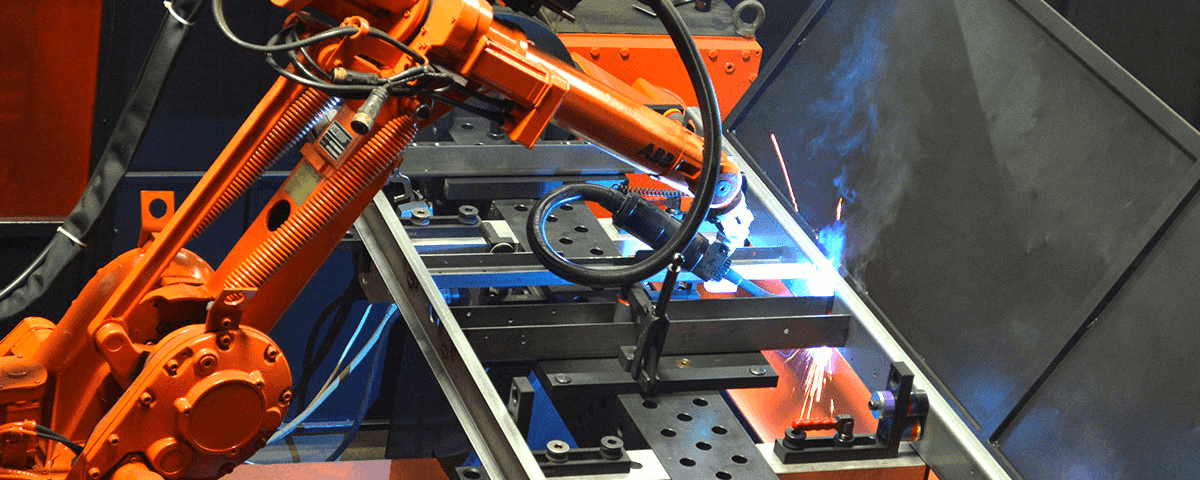

1. FABRICATION INDUSTRY

Robotic Welding technology will also be advantageous to the metal manufacturing sector. Robotic welding may make it possible to do more tasks than ever because many manufacturing companies frequently take on multiple projects. No matter the business, welding provides a terrific way to finish one-off or continuing projects, from marine equipment to scissor lifts.

2. RAIL INDUSTRY

Precision Cutting: How Accurate is Plasma Cutting Technology?

Throughout the year, the rail sector is frequently required to build a wide variety of vehicle units for businesses. Companies may place hundreds of orders simultaneously because the rail sector often sees repeat orders of comparable rail cars for months. For instance, certain train companies want metal bolsters to join the ends of container cars. Robotic welding technology can help these companies by generating different bolsters more quickly.

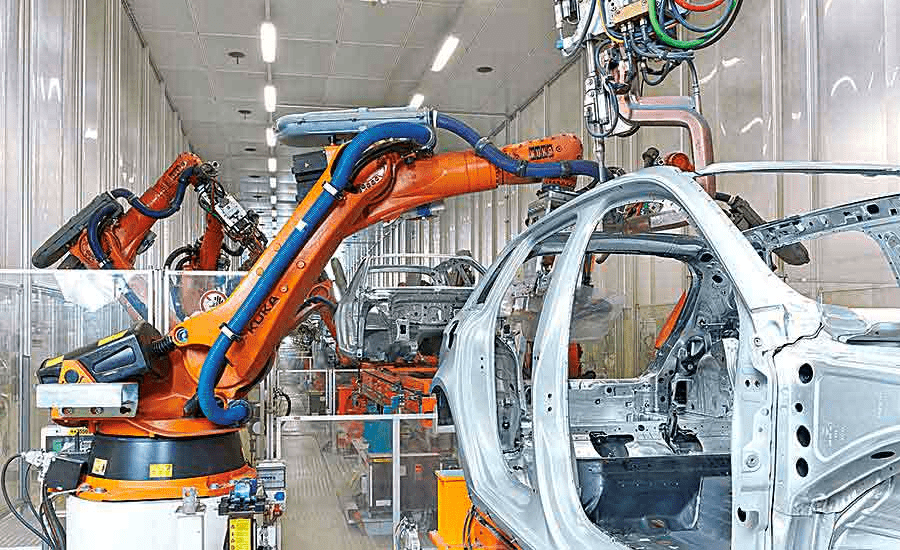

3. AUTOMOTIVE INDUSTRY

The car sector needs quick production capabilities and complicated state and federal safety criteria to comply with rules and regulations. A brake press or a cast is used to create several automotive pieces, ensuring the frame is constructed correctly. However, welding must fuse the parts to one another to ensure that the car comes together as a seamless whole.

Welding may be helpful in more automotive uses as well:

- Engines: Welding is essential to ensuring that engines are long-lasting and adequately affixed to the vehicle.

- Pumps: Welding may be necessary for car water pumps to join complex metals and pieces.

- Metal fasteners: Metal fasteners are frequently employed when building cars, and welding helps to fasten parts permanently.